External Wall Insulation Board - XPS (1 board = 0.72m²)

External Wall Insulation Board - XPS (1 board = 0.72m²) - 30mm (Single Board - 0.72m2) is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

Please proceed to checkout to get an estimate of the delivery time for this product.

Returning an item

Returning an item

If you are not completely satisfied with your purchase, please contact our customer service team.

Description

Description

Upgrade your project with Extruded Polystyrene (XPS) insulation boards, the modern solution for reliable, long lasting thermal performance. Designed with a closed cell structure, these high density boards deliver outstanding thermal insulation, moisture resistance, and compressive strength - making them a trusted choice for both residential and commercial applications.

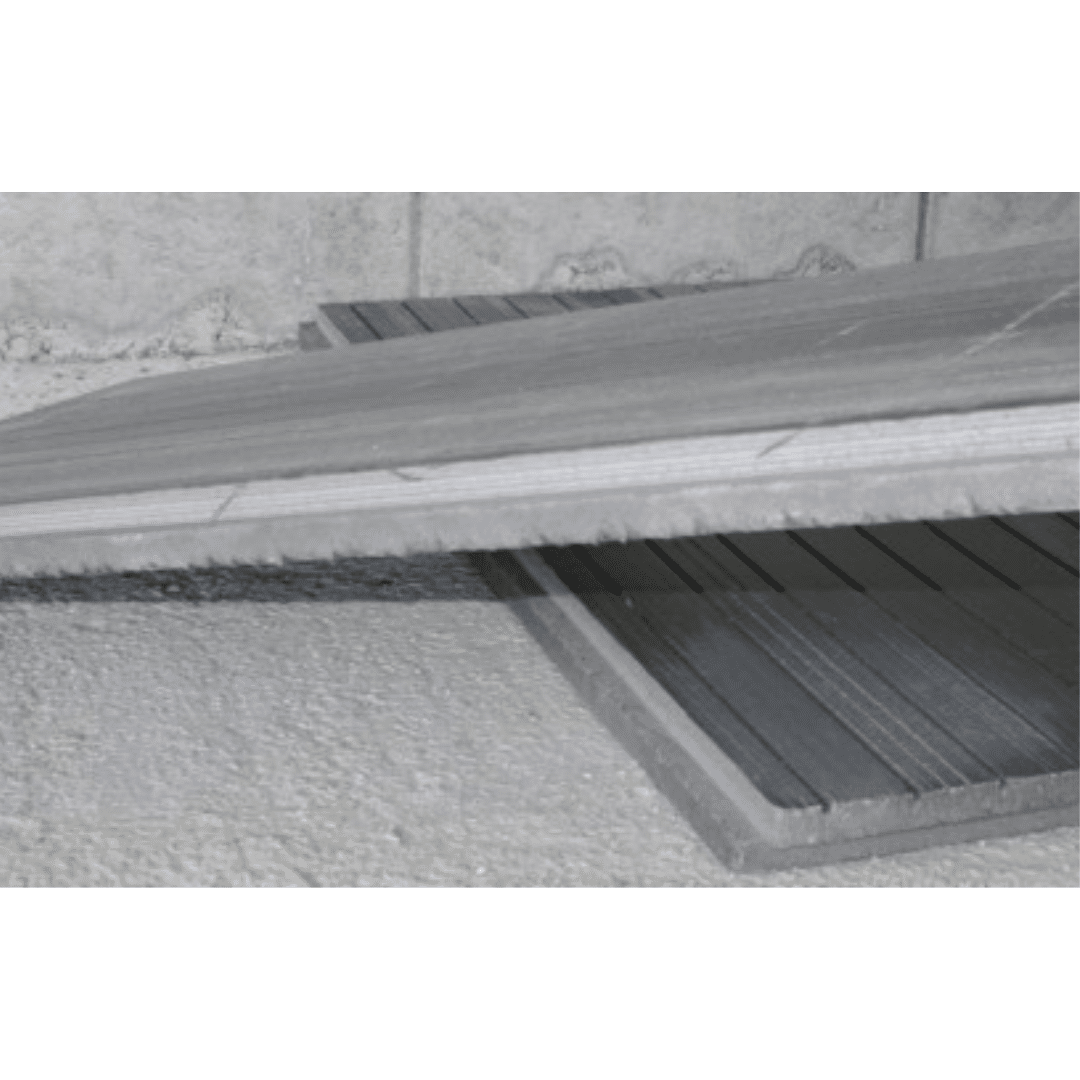

Whether you're insulating below DPC, extending concrete windowsills, or looking for a durable alternative to EPS, XPS boards provide a smooth, ready to use surface that's compatible with a wide range of systems.

- Versatile Application - Ideal for timber, masonry, and system built properties. Perfect for tile hanging and as a base for render systems.

- Superior Thermal Performance - Closed cell structure ensures low thermal conductivity.

- Moisture and Weather Resistant - Hydrophobic design prevents water absorption.

- Lightweight Yet Strong - High mechanical strength without adding unnecessary weight.

- Durable and Chemical Resistant - Withstands exposure to cement, mortar, paints, seawater, and more.

- Safe and Reliable - Contains flame retardant (avoid direct flames or ignition sources).

Installation Guide

For best results, prepare the surface with a protection mat before applying insulation. We recommend using a hot knife or hot wire cutter for precise, mess free cutting.

XPS boards should be installed according to your project plan or architectural brief. For below DPC applications or sill insulation, fix using a quick drying mortar or adhesive such as EWI-225 Premium Basecoat. Once secured and dry, protect the area from water or UV exposure. When ready, apply basecoat and fibreglass mesh, followed by your chosen topcoat system.

Specifications

Specifications

-

custom.download_information

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Share information about this product with your customers.